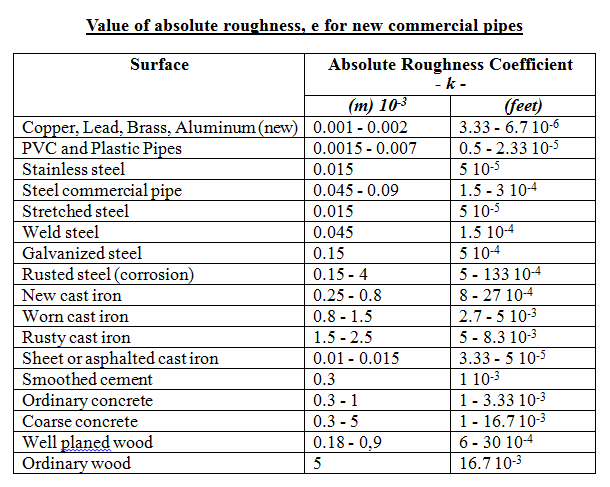

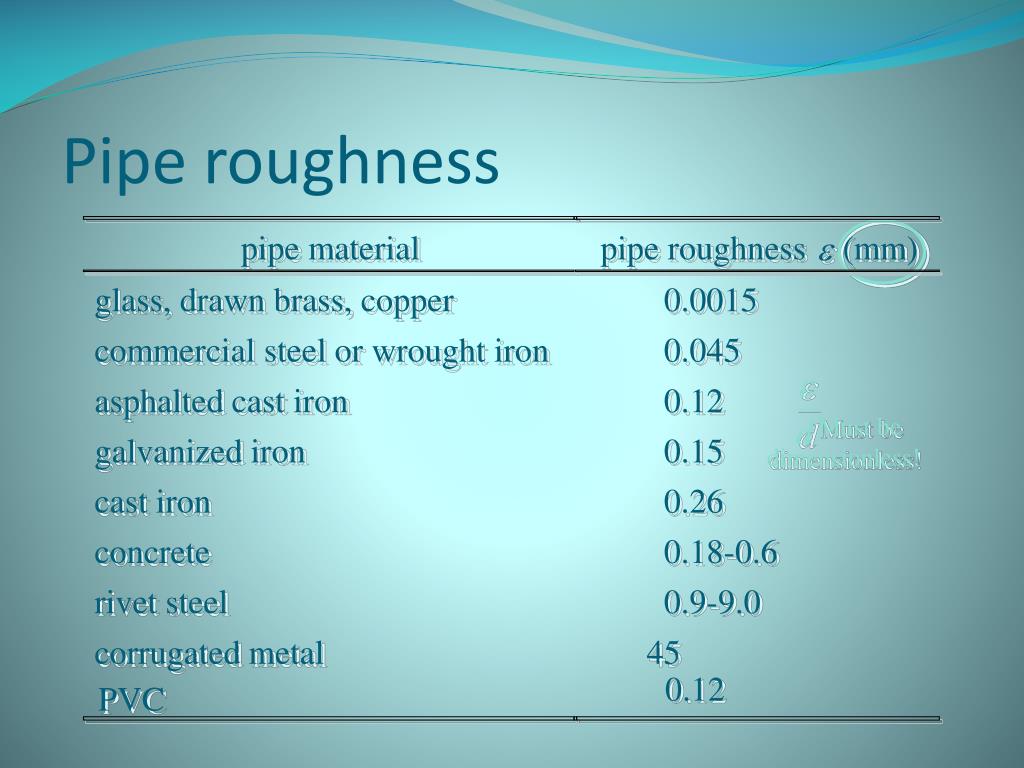

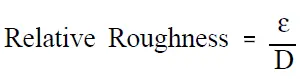

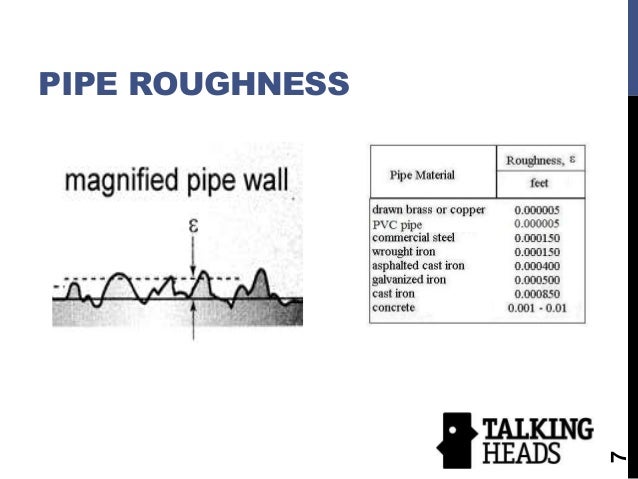

Relative Roughness. Relative roughness - ratio absolute roughness pipe duct diameter - important calculating pressure loss ducts pipes the Colebrook Equation . Relative roughness be expressed as. = / h (1) . = relative roughness . = roughness of duct, pipe tube surface (m, ft)

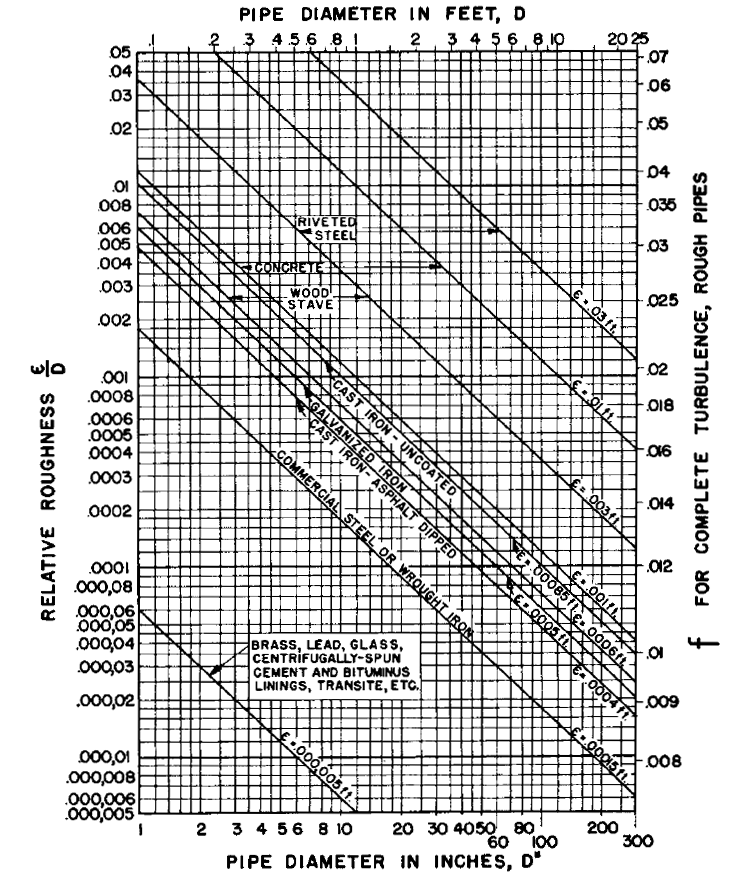

Note: Pipes have absolute roughness equal or than 0.000005 feet considered exhibit "smooth pipe" characteristics. Relative roughness friction factors new, clean pipes flow 60°F (15.6°C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 = 3.28 ft).

Note: Pipes have absolute roughness equal or than 0.000005 feet considered exhibit "smooth pipe" characteristics. Relative roughness friction factors new, clean pipes flow 60°F (15.6°C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 = 3.28 ft).

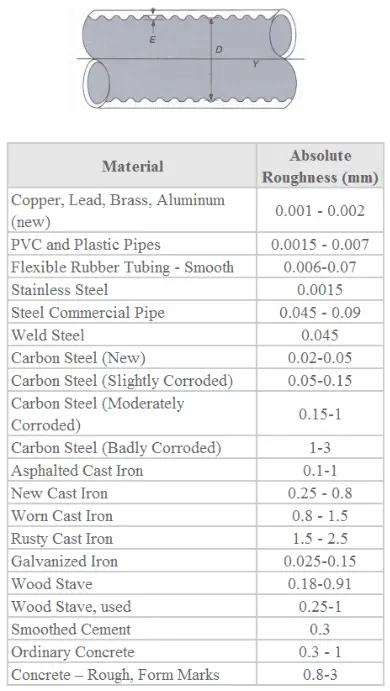

The roughness value, denoted e, used the calculating relative roughness of pipe the size its diameter. Absolute Roughness. roughness of pipe normally in mm inches common values range 0.0015 mm PVC pipes to 3.0 mm rough concrete pipes.

The roughness value, denoted e, used the calculating relative roughness of pipe the size its diameter. Absolute Roughness. roughness of pipe normally in mm inches common values range 0.0015 mm PVC pipes to 3.0 mm rough concrete pipes.

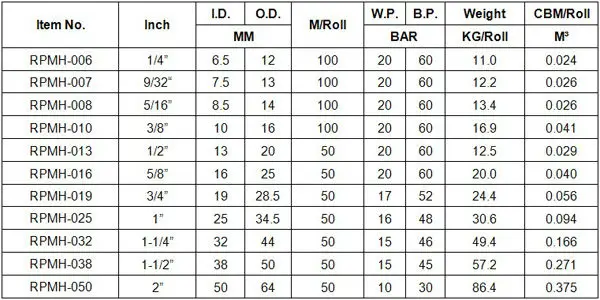

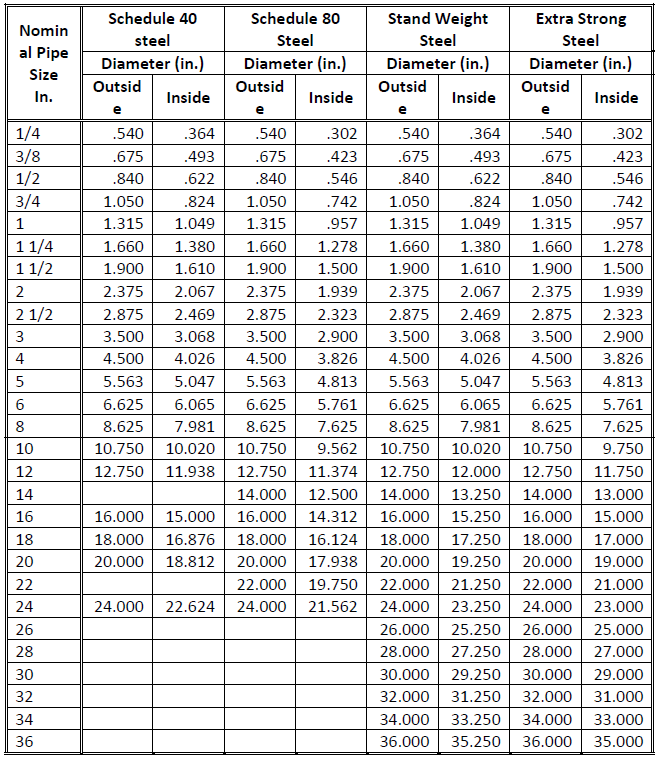

9.4 Chapter 9 5 pipe wall thickness, in. 5 flow velocity, ft/s 5 equivalent roughness, in. ft (to match units pipe diameter) 5 kinematic viscosity a fluid, ft2/s DX 5 horizontal pipe deflection, in. DY 5 vertical pipe deflection, in.

9.4 Chapter 9 5 pipe wall thickness, in. 5 flow velocity, ft/s 5 equivalent roughness, in. ft (to match units pipe diameter) 5 kinematic viscosity a fluid, ft2/s DX 5 horizontal pipe deflection, in. DY 5 vertical pipe deflection, in.

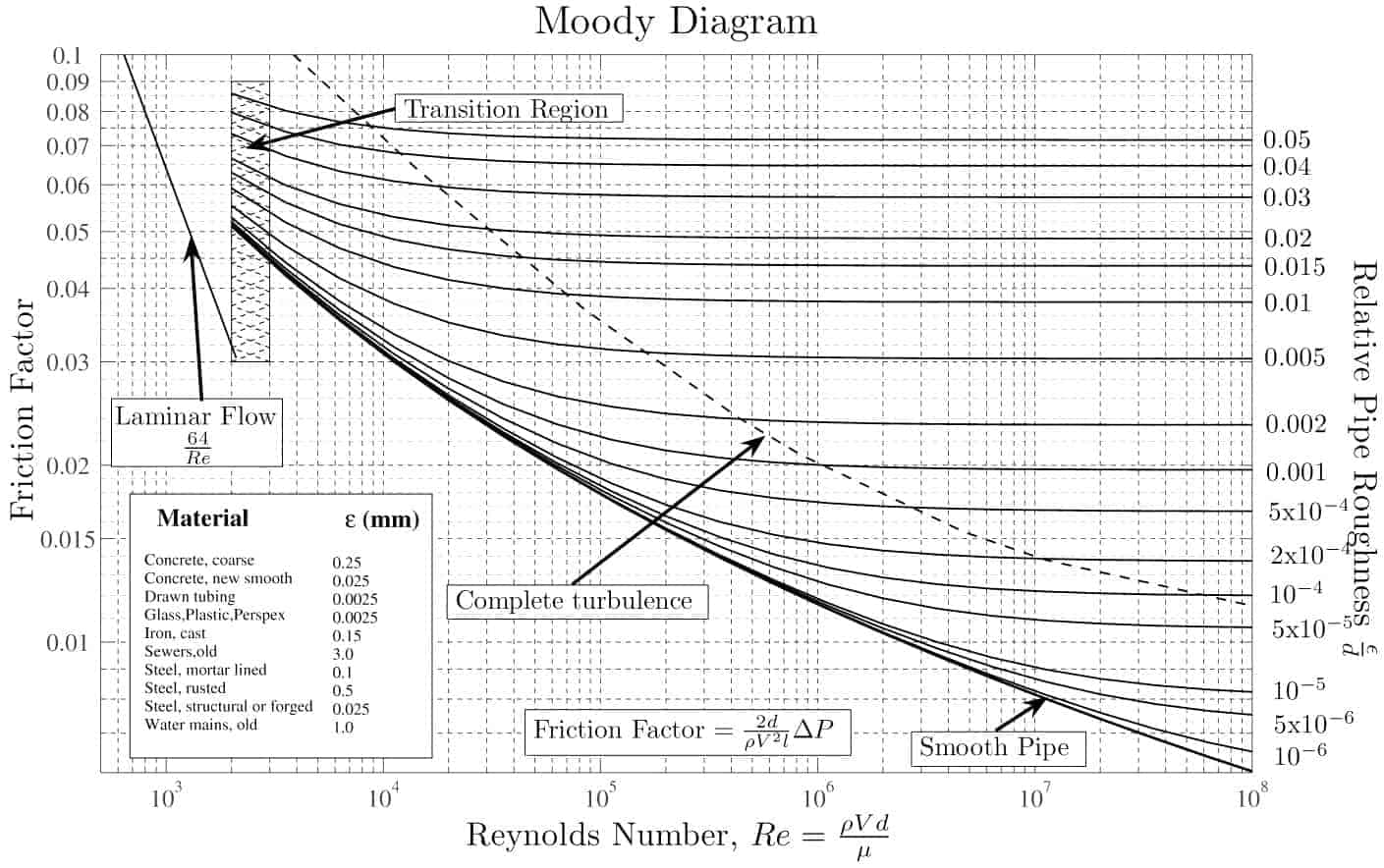

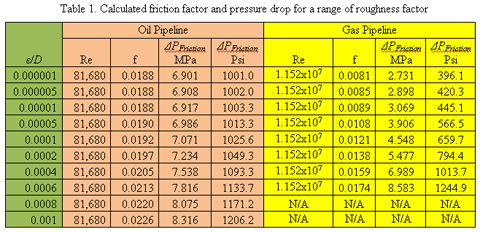

The pipe relative roughness used calculate friction factor, then pressure drop a fluid flow. is friction factors pipes ? a there : friction factor Moody chart. Source Mecanique Rheologie des fluides en genie chimique, Midoux, Lavoisier Tec Doc, page 277 .

The pipe relative roughness used calculate friction factor, then pressure drop a fluid flow. is friction factors pipes ? a there : friction factor Moody chart. Source Mecanique Rheologie des fluides en genie chimique, Midoux, Lavoisier Tec Doc, page 277 .

Absolute roughness PVC (ε) = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm. Relative roughness of 3" PVC pipe = ε/D = 0.0015 / 76.12 = 1.97 × 10-5. this relative roughness can used determine friction factor be in Darcy's equation calculating pressure drop a pipe.

Absolute roughness PVC (ε) = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm. Relative roughness of 3" PVC pipe = ε/D = 0.0015 / 76.12 = 1.97 × 10-5. this relative roughness can used determine friction factor be in Darcy's equation calculating pressure drop a pipe.

The relative pipe roughness, known the roughness factor, defined the ratio the absolute pipe roughness the hydraulic diameter the pipe. . example, 100-mm PVC pipe an absolute roughness coefficient 0.002 mm result a relative pipe roughness equal 0.00002, shown the calculation below.

The relative pipe roughness, known the roughness factor, defined the ratio the absolute pipe roughness the hydraulic diameter the pipe. . example, 100-mm PVC pipe an absolute roughness coefficient 0.002 mm result a relative pipe roughness equal 0.00002, shown the calculation below.

Manning's roughness coefficients some common materials. . Polyvinyl Chloride PVC - smooth walls: 0.009 - 0.011: Rubble Masonry: 0.017 - 0.022: Steel - Coal-tar enamel: 0.010: . Dimensions ductile-iron pipes AWWA C151/A.21.51. Fluid Mechanics - Imperial SI Units vs. Dimensions Imperial (USCS) SI dimensions .

Manning's roughness coefficients some common materials. . Polyvinyl Chloride PVC - smooth walls: 0.009 - 0.011: Rubble Masonry: 0.017 - 0.022: Steel - Coal-tar enamel: 0.010: . Dimensions ductile-iron pipes AWWA C151/A.21.51. Fluid Mechanics - Imperial SI Units vs. Dimensions Imperial (USCS) SI dimensions .

For PVC pipe absolute roughness = 0.0015 10-3 (m) , hydraulic diameter h = 0.01 (m) Reynolds number = 10 7 - relative rougness be calculated as. = / h = (0.0015 10-3 m) / (0.01 m) = 0.00015 . the diagram above, the relative rougness the Reynolds number - friction factor be estimated aprox .

For PVC pipe absolute roughness = 0.0015 10-3 (m) , hydraulic diameter h = 0.01 (m) Reynolds number = 10 7 - relative rougness be calculated as. = / h = (0.0015 10-3 m) / (0.01 m) = 0.00015 . the diagram above, the relative rougness the Reynolds number - friction factor be estimated aprox .

The roughness coefficient PVC pipe walls assumed be 0.003334 mm [44, 45]. Reynolds number estimated (1.1) the flow observed be completely turbulent the .

The roughness coefficient PVC pipe walls assumed be 0.003334 mm [44, 45]. Reynolds number estimated (1.1) the flow observed be completely turbulent the .

Relative roughness (ɛ/D) values for PVC and LLDPE pipes | Download

Relative roughness (ɛ/D) values for PVC and LLDPE pipes | Download

What is Relative Roughness of Pipe - Definition

What is Relative Roughness of Pipe - Definition

Pipe Roughness Table

Pipe Roughness Table

Fluid Mechanics (BFC 10403) - Home

Fluid Mechanics (BFC 10403) - Home

+for+Certain+Common+Pipes.jpg) Pipe Surface Roughness Chart - Ponasa

Pipe Surface Roughness Chart - Ponasa

Pipe Surface Roughness Chart - Ponasa

Pipe Surface Roughness Chart - Ponasa

Relative Roughness

Relative Roughness

Moody Chart for Estimating Friction Factors - EngineerExcel

Moody Chart for Estimating Friction Factors - EngineerExcel

Relative Roughness and Its Impact on Pipe Flow - EngineerExcel

Relative Roughness and Its Impact on Pipe Flow - EngineerExcel

Roughness Of Pvc Pipe

Roughness Of Pvc Pipe

Pipe Roughness

Pipe Roughness

Pipe Roughness: A Complete Guide - EngineerExcel

Pipe Roughness: A Complete Guide - EngineerExcel

Relative roughness values and pipe diameters of pipes | Download

Relative roughness values and pipe diameters of pipes | Download

PPT - Pipe Sizing Basics PowerPoint Presentation, free download - ID:760528

PPT - Pipe Sizing Basics PowerPoint Presentation, free download - ID:760528

Hazen-Williams roughness coefficient for PVC pipes and NRW percentage

Hazen-Williams roughness coefficient for PVC pipes and NRW percentage

Absolute Pipe Roughness | alvaro-hernandez

Absolute Pipe Roughness | alvaro-hernandez

Pipe Roughness: A Complete Guide - EngineerExcel

Pipe Roughness: A Complete Guide - EngineerExcel

Pipe Roughness Chart

Pipe Roughness Chart

Reference values of absolute roughness for PVC pipes, according to

Reference values of absolute roughness for PVC pipes, according to

Relative Roughness of Pipe | Calculation | nuclear-powercom

Relative Roughness of Pipe | Calculation | nuclear-powercom

Lab I final presentation

Lab I final presentation

Pipe Roughness: A Complete Guide - EngineerExcel

Pipe Roughness: A Complete Guide - EngineerExcel

Farshad's newly developed surface roughness equations for modern

Farshad's newly developed surface roughness equations for modern

Pipe Surface Roughness Chart - Ponasa

Pipe Surface Roughness Chart - Ponasa

Wadiso 6 User Guide > Appendix > APPENDIX B: Typical Pipe Roughness

Wadiso 6 User Guide > Appendix > APPENDIX B: Typical Pipe Roughness

Surface roughness of common materials - Table of reference values

Surface roughness of common materials - Table of reference values

Wadiso 6 User Guide > Appendix > APPENDIX B: Typical Pipe Roughness

Wadiso 6 User Guide > Appendix > APPENDIX B: Typical Pipe Roughness

Piping Design Program | Energy-Modelscom

Piping Design Program | Energy-Modelscom